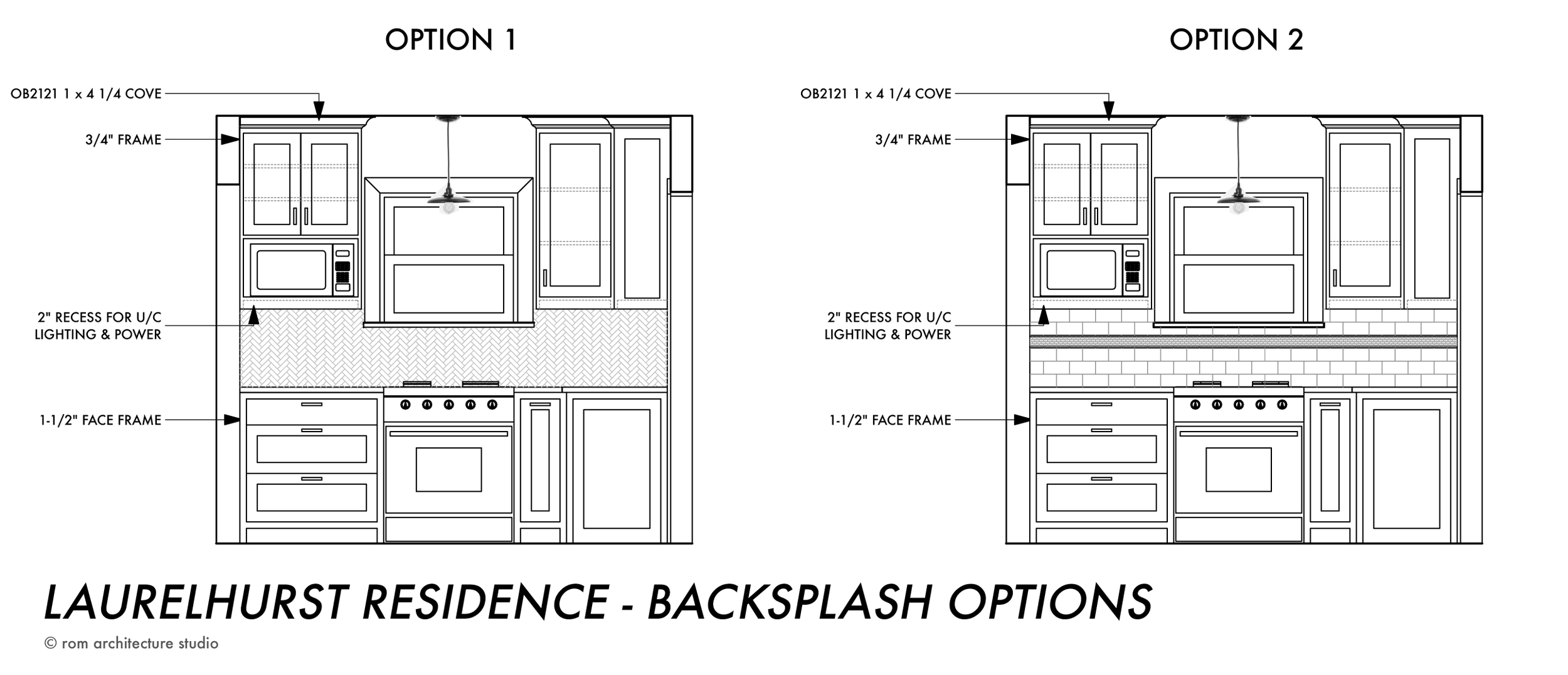

We asked our general contractor to give us a total installed price for both options. Surprisingly, the additional labor to install the less expensive tile made Option 2 MORE expensive than Option 1. The labor to install each piece individually, plus additional time to determine the best layout in the field (to minimize small pieces), more than closed the price gap of the materials per square foot. This would not have been true if Option 1 also required piece-by-piece installation and fussy layout calculations in the field, but since the herringbone mosaic came mounted on a mesh in 12"x12" interlocking pieces, the labor factor was significantly less.

PURCHASE INCREMENTS AND SUBCONTRACTOR LIABILITY

Some materials have an even larger price difference between the material cost and the total installed cost. One reason is that some items must be purchased in certain increments, regardless of the amount needed -- such as certain tiles that are sold by the box and stones that are sold in whole slabs.

When fragile or difficult to fabricate materials are being handled and shaped, there will also be a liability factor in the subcontractor's pricing. After all, if they break the slab, they will have to purchase and fabricate a replacement.

Example:

Upgrading to manufactured quartz from plastic laminate may seem like a small splurge if you rely upon square foot costs to make your judgment (see the yellow highlighted cells in the spreadsheet, below). However, once labor, fabrication, and mark-ups are added, the multiplier is much higher (green cells vs. yellow cells, below).